LIQUID LPG RELIEF

Problem Description

This example presents the dynamic of a LPG relief from a truck due to a leak located on the bottom of the container. Unfortunately this scenario is that of the accident occurred at the Viareggio railway station on the night of June, 29 2009, where the released LPG caused a large number of fatalities.

Basic data are taken from the paper:

S. Brambilla, R. Totaro, D. Manca, “Simulation of the LPG release, dispersion, and explosion in the Viareggio railway accident”, CISAP4 – 4th International Conference on Safety & Environment in Process Industry, 14-17 March 2010, Florence, Italy.

The LPG container is simulated as a horizontal vessel with a diameter of 3.04 m and a length of 15.95 m, filled with 45 t of LPG at 15 bar.

The leak is modeled as a hole with a surface of 100 cm2 and a discharge coefficient equal to 0.6.

The simulation assume that a horizontal vessel full of liquid LPG is punctured on the bottom part.

Using XPSIM, the simulation is performed using the DEPRESS unit operation where the release is specified to be LIQ as located in the bottom part.

Since the liquid is at saturated conditions, it is subject to a flash during discharge as soon as the pressure is lowered.

The flow discharge is critical and due to the two-phases the flow-rate is lower than experienced for either gas or liquid as separate phase.

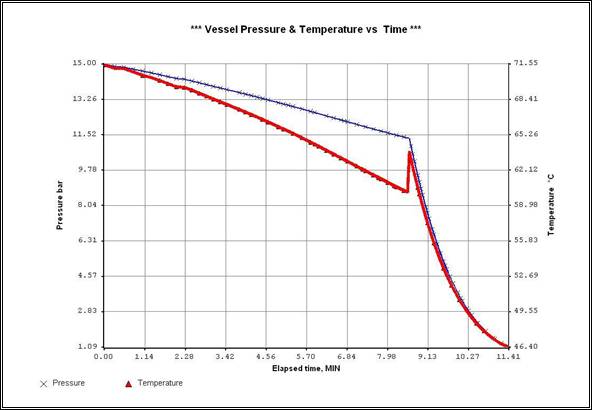

During the liquid discharge the internal pressure is in part maintained by the evaporation of the liquid LPG, so that when all the liquid has been discharged the vessel is still at about 10 bar.

Only the subsequent vapor discharge can rapidly depressurize the vessel to the atmospheric pressure.

Two calculations are presented. The first calculation assumes, according to the quoted paper, that the LPG is pure propane.

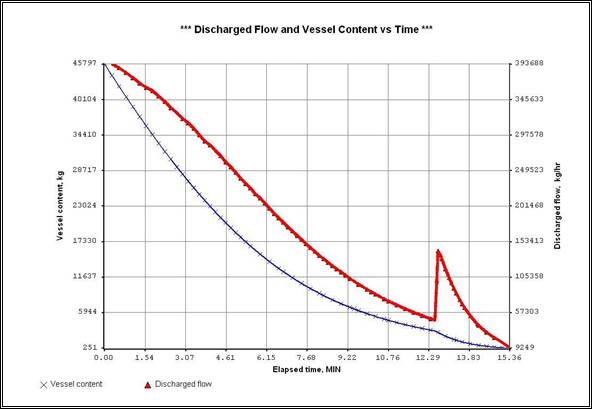

The following graphs show respectively:

· the vessel pressure and temperature

· discharged flow-rate and vessel content

Fig. 1 – Pure Propane relief

Fig. 2 – Pure Propane relief

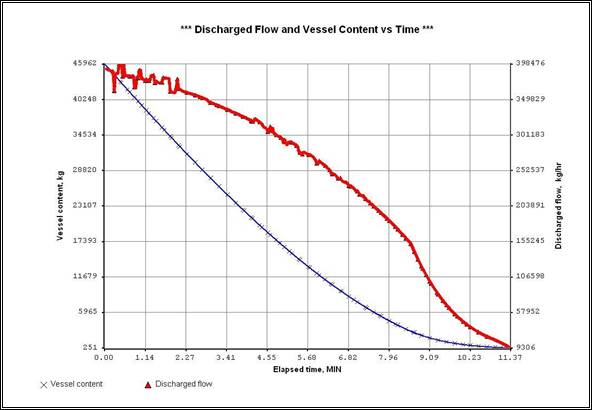

A second calculation considers that the fluid is a commercial mixture of C3 and C4 hydrocarbons (30% of C3 and 67% of C4 with small quantities of C2 and C5).

Fig. 3 – Commercial LPG (C3+C4 mixture)

Fig. 4 – Commercial LPG (C3+C4 mixture)

Due to the higher density of the fluid, the discharge time is lower.

Generated Keyword Input File

<XPSIM> ...generated by XpsimWin v.1.08 ...

*

*

RUN ID=VIAREGGIO CUSTOMER=STAFF PROJECT=LPG-RELEASE-VIAREGGIO

*

DESC SIMULATION OF THE LPG RELEASE AT VIAREGGIO STATION

*

DIMENSION INPUT SI PRES=BAR

*

*

System Data

*

*

*

CHEMCOMP C2 / C3 / NC4 / NC5

*

THERMSET UID=M1

METHODS K=SRK HS=LK CP=LK D=LK IV=LK TRAN=IDEAL SURT=IDEAL

*

*

Flowsheet Data

*

*

*

STREAM=S1 TEMP=30 PRES=15 RATE(W)=1000 XBASIS=V

COMP C2:2 / C3:30 / NC4:67 / NC5:1

*

FLASH IN S1 OUT S2(V) S3(L) UID=F1

CALC BUB PRES=15

*

PSD IN S1 OUT S6 UID=PSD1

PARA CALC=2 METHOD=MXFLOW PREL(BAR)=15 TREL=30 PBACK(BAR)=1

SIZE DEVICE=VALVE AREA(CM2)=100 KB=1 KC=1 KD=0.6

*

DEPRESS IN S1 UID=DEP1

VESSEL TYPE=HORZ DIAM(MT)=3.04 LENGTH(MT)=15.95 CHARGE(W)=45000 +

FEED=BUBT PRES=15

CALC MODEL=1 PHASE=LIQ PRELIEF=15 PFINAL=1.1 TDEPRES(MIN)=60 PBACK=1

PSV MODEL=6 CONST=132

PRINT WRATE

*

*

END